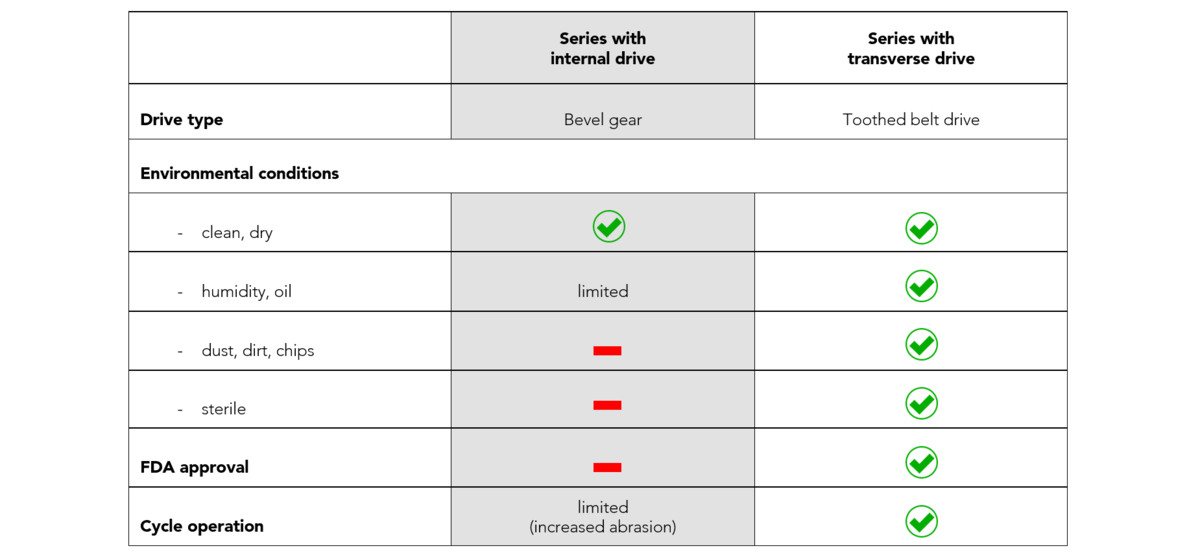

Anyone who has ever asked us about a small conveyor knows that we will ask a few questions about the project in advance. For the selection of the right type of conveyor, among others the environmental conditions at the place of use, FDA requirements and the operating mode (cyclical operation or normal operation) are decisive. The following overview shows the differences:

The series with internal drive is very popular - due to its simple integration into existing systems with little space without any interfering contours from the motor. But the bevel gear drive used has its pitfalls - as soon as dirt gets into the gear box ...

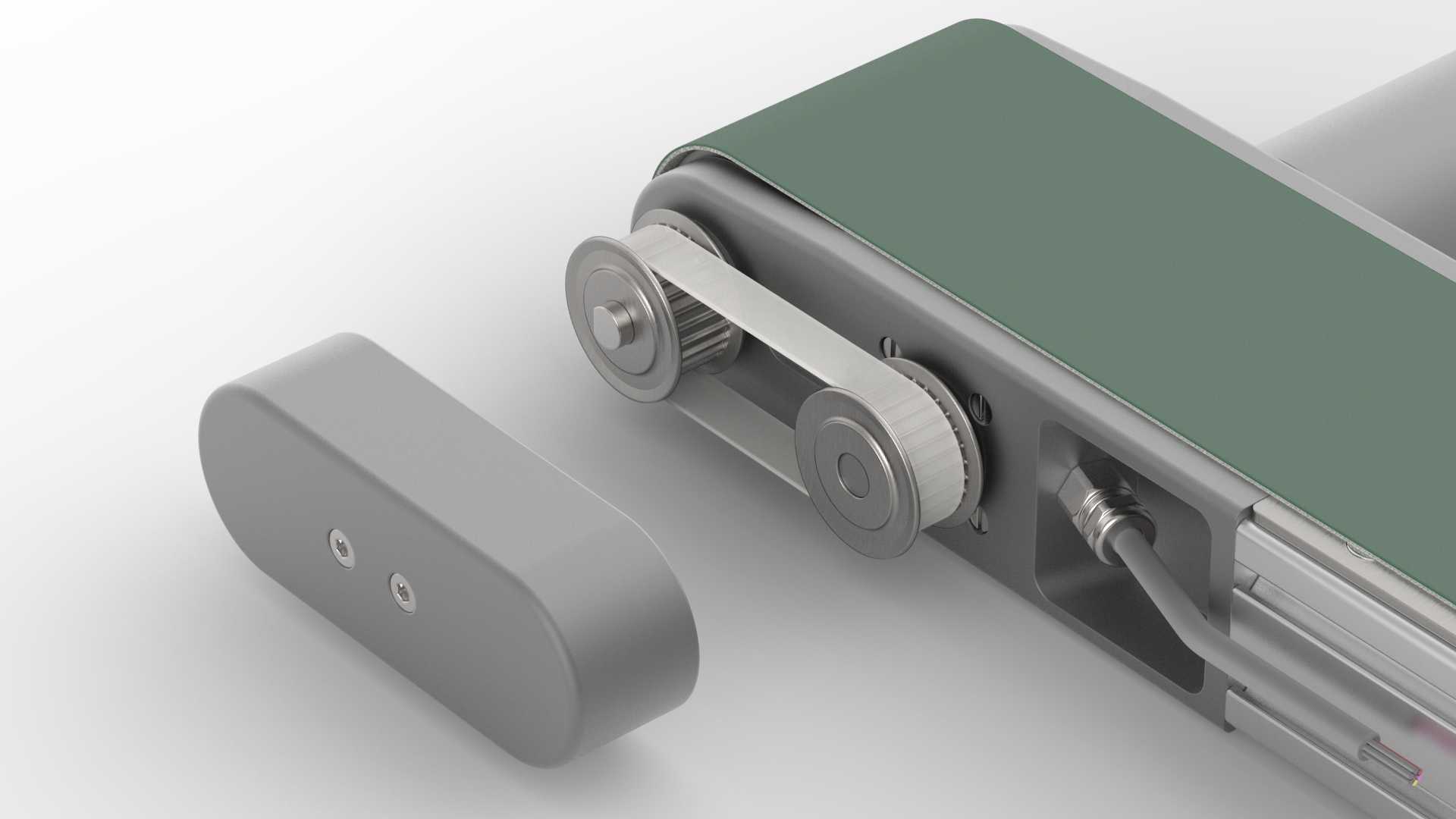

The small conveyors of the series with internal drive are driven by a bevel gear. The drive wheel and the corresponding bevel gear set are freely accessible on the side of the drive unit under the belt (see picture). Unclean environmental conditions - especially dust, dirt or chips - can block the bevel gear unit. If dirt gets under the belt, it is difficult to clean at this point. In the worst case, this can lead to transmission failure and thus engine damage. If the conveyor is to run in cyclic operation, this also leads to increased abrasion of the bevel gear.

We also advise our customers against using this type of drive in sterile environments, such as in food production or in the manufacture of pharmaceutical products (FDA). Conversely, not only dirt can enter, but also minimal amounts of grease / lubricant can escape from the bevel gear unit.

The better choice for unclean environmental conditions is our series with transverse drive. The motor is completely built into the drive housing and the conveyor is driven by a toothed belt drive positioned on the side. The drive wheel and the deflection roller under the belt are seamless and do not allow dirt or chips to accumulate. If necessary, there is even the option of sealing the drive housing completely against liquids or dust. The motor is protected and vice versa there is no contamination from the drive; thus the FDA suitability is guaranteed.

Already have a clear idea about the conveyor you want? Our product finder can help you find what you are looking for fast.

Our selection of conveyor belts is just as varied as our product range. Combine the appropriate belt with our conveyor models.

For speed control we also have suitable electronic setpoint devices in our range.

Cookie settings

This website uses cookies that enable you to use services offered by external providers, such as YouTube or Google Maps. The legal basis here is Art. 6 DSGVO (1) a.

Here you can object to the anonymized recording of your user behavior by MATOMO. For this purpose, we store a cookie on your computer to respect this decision also on subsequent visits.

Please note that depending on your settings, some functions may not be available.

You can find more information in our Privacy policy