Our new videos (image film, career film, company headquarters in Westerstetten) give a small but fine insight into our company.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/e/d/csm_Vetter_Geb%C3%A4ude_75c85c4a6a.jpg)

“Helping is strong,” says the Johanniters, who have been successfully providing first aid to children in day care centers, kindergartens, schools and youth groups for years. A commitment that we are very happy to join again.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/website/Aktuelles/Ersthelfer_von_morgen_2022.jpg)

In this video, our customer Laserfix24 shows his complete system for laser marking - including the Vetter small conveyor for component feeding and removal.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/7/9/csm_Laserfix24_11becd0a88.jpg)

Also this year we successfully passed the second audit of our quality management system according to ISO 9001:2015!

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/website/Aktuelles/ISO_Zertifizierung_2023.png)

To illustrate the connection and commissioning of our Vetter small conveyors and setpoint devices, we have created a video series for you in German and English. Just take a look at it!

“Helping is strong,” says the Johanniters, who have been successfully providing first aid to children in day care centers, kindergartens, schools and youth groups for years. A commitment that we are very happy to join again.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/website/Aktuelles/Ersthelfer_von_morgen_2022.jpg)

With this small conveyor, we have further miniaturized our modular kit series to a belt width of just 10 mm. A small and flexible conveyor solution with timing belt and easydrive system was created.

One of our customers designed a double conveyor ("sandwich") based on our Vetter modular kit - tailored to his requirements. We were absolutely excited and put the plan into action!

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/7/2/csm_Vetter_Sonderf%C3%B6rderband_Vakuum2_609314abdb.jpg)

After a successful audit, Vetter Kleinförderbahnen GmbH is now ISO 9001:2015 certified!

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/website/Aktuelles/ISO_Zertifizierung.png)

In October, Vetter Kleinförderbänder GmbH celebrates its 10th anniversary!

“Helping is strong,” says the Johanniters, who have been successfully providing first aid to children in day care centers, kindergartens, schools and youth groups for years. A commitment that we are very happy to join.

After moving to our new building, we have now expanded our machine park in the assembly!

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/5/c/csm_Vetter_S%C3%A4ge_b560ffad72.jpg)

You need a conveyor with a very special "grip" for your products? With our small conveyor with vacuum function, we can easily suck in your products on the belt!

Test setup on customer request: The task is the precise hand over between two conveyors through electronically controlled synchronous operation. Each conveyor should have two tracks due to the desired transport width.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/website/Aktuelles/F%C3%B6rderband-eletronischer-Synchronlauf-2-spurig.jpg)

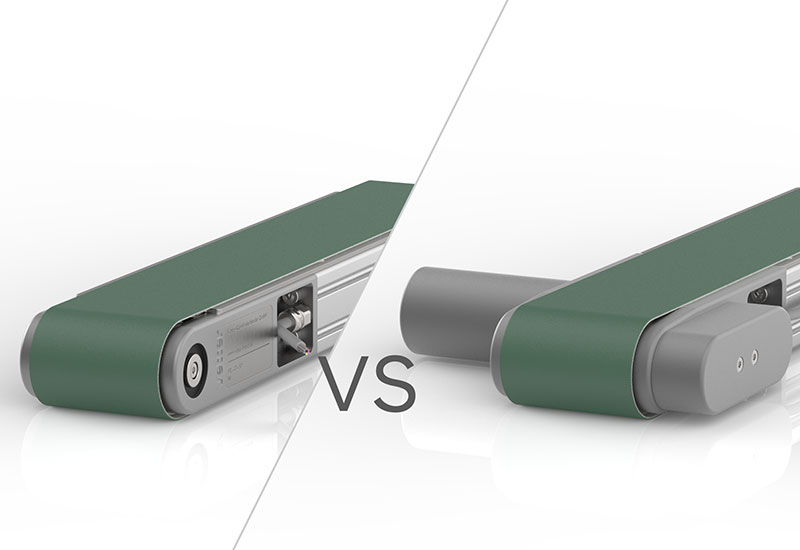

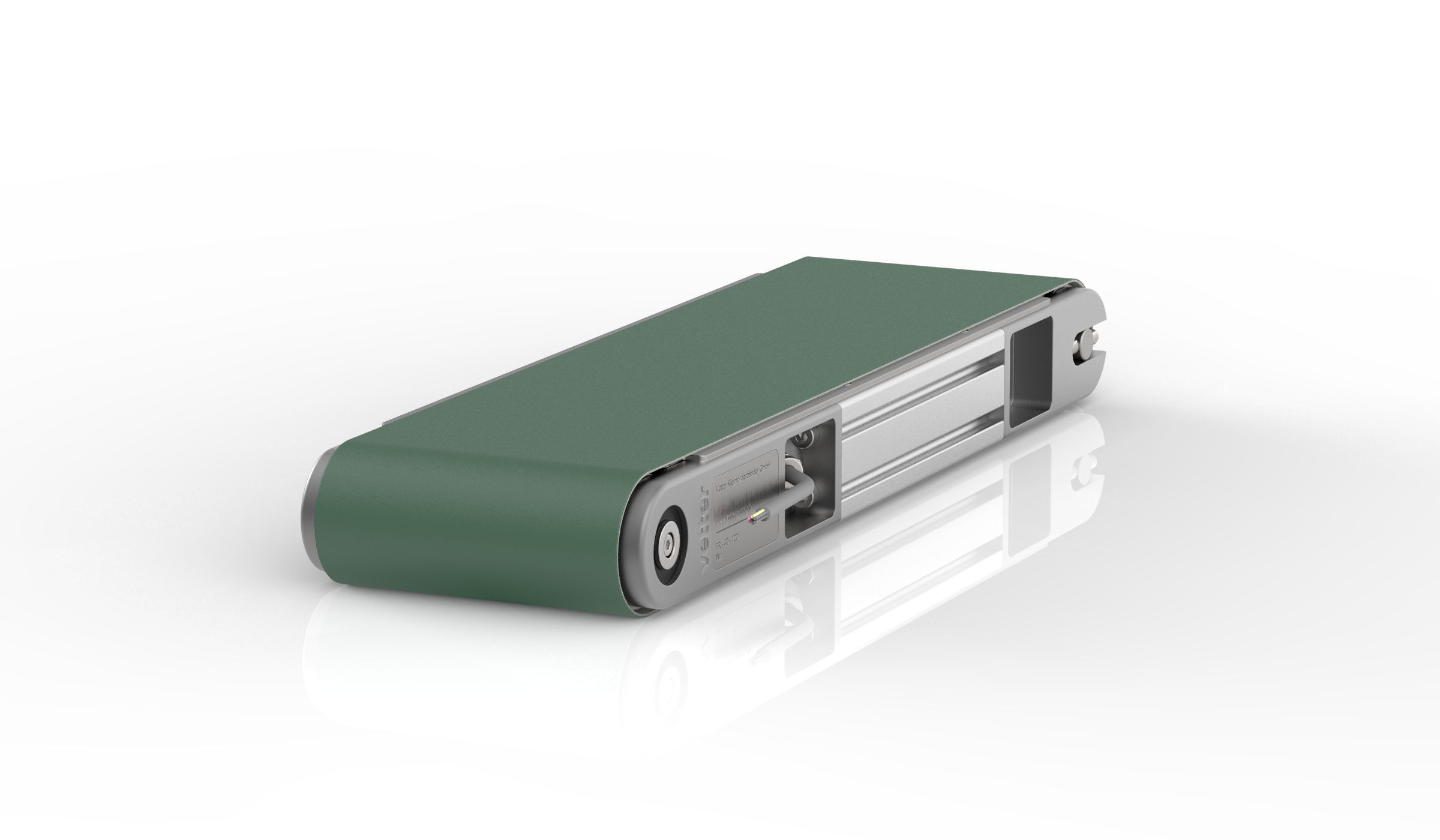

Our customers often use small conveyors with internal or transverse drives. When choosing which of the two types is suitable for the area of application, certain criteria can help, which are explained in the article.

In our latest collaboration with Yuanda Robotics GmbH, our FR-40-200 small conveyor with internal drive is used for precise and reliable feeding.

The heart of our small conveyors are the internal drives. For years we have been using modern microdrives from Faulhaber (brushless DC motors with speed controller). Reliability and service life are particularly important.

We have been in our new building in Westerstetten for three months. Who would have thought last year that the completion would be in the middle of a “crisis”. Despite lower incoming orders and occasional short-time work, we are in good spirits: It is important for us how we deal with such a situation.

Now the time has come: We have moved into our new business and production building in Westerstetten!

Thanks to the energy and resource-efficient construction of our new business and production building in accordance with the KfW-55 standard, we were able to obtain the "energy-efficient operating building - new construction of an efficiency house" promotional loan from L-Bank for financing.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/website/Aktuelles/Neubau/Vetter_Katrin_Steeb_F%C3%B6rderkredit.jpg)

We continue to grow and are currently in the middle of the construction project for our new business and production building in Westerstetten (5 km from the previous location). The move to Westerstetten is planned for spring 2020.

At Motek in Stuttgart, the international trade fair for production and assembly automation, we presented numerous applications from our small conveyor technology program from October 7th to October 10th, 2019.

Cookie settings

This website uses cookies that enable you to use services offered by external providers, such as YouTube or Google Maps. The legal basis here is Art. 6 DSGVO (1) a.

Here you can object to the anonymized recording of your user behavior by MATOMO. For this purpose, we store a cookie on your computer to respect this decision also on subsequent visits.

Please note that depending on your settings, some functions may not be available.

You can find more information in our Privacy policy