Our flexible design makes various versions and individual extensions to our small conveyors possible, no matter whether the application calls for integrated lateral guides, two track or multi track solutions, round belts, a knife edge or a shaft stub. We also provide you with 3D models for every custom solution.

On this page you will find a selection of special solutions which we have manufactured for our customers according to individual specifications. Talk to us and benefit from our experience.

Floating conveyor? Almost. At least the small conveyor with bracket can be set up wherever it is needed. It can be dismantled and stowed just as quickly. This simple extension offers a great advantage, especially on desk workstations.

We use aluminum profiles from Item for our conveyors. For example, we can place slot nuts (M3, M4 or M5 in steel or stainless steel) into the profile groove provided (e.g. 5 mm groove) and flexibly attach various brackets to the conveyor if desired.

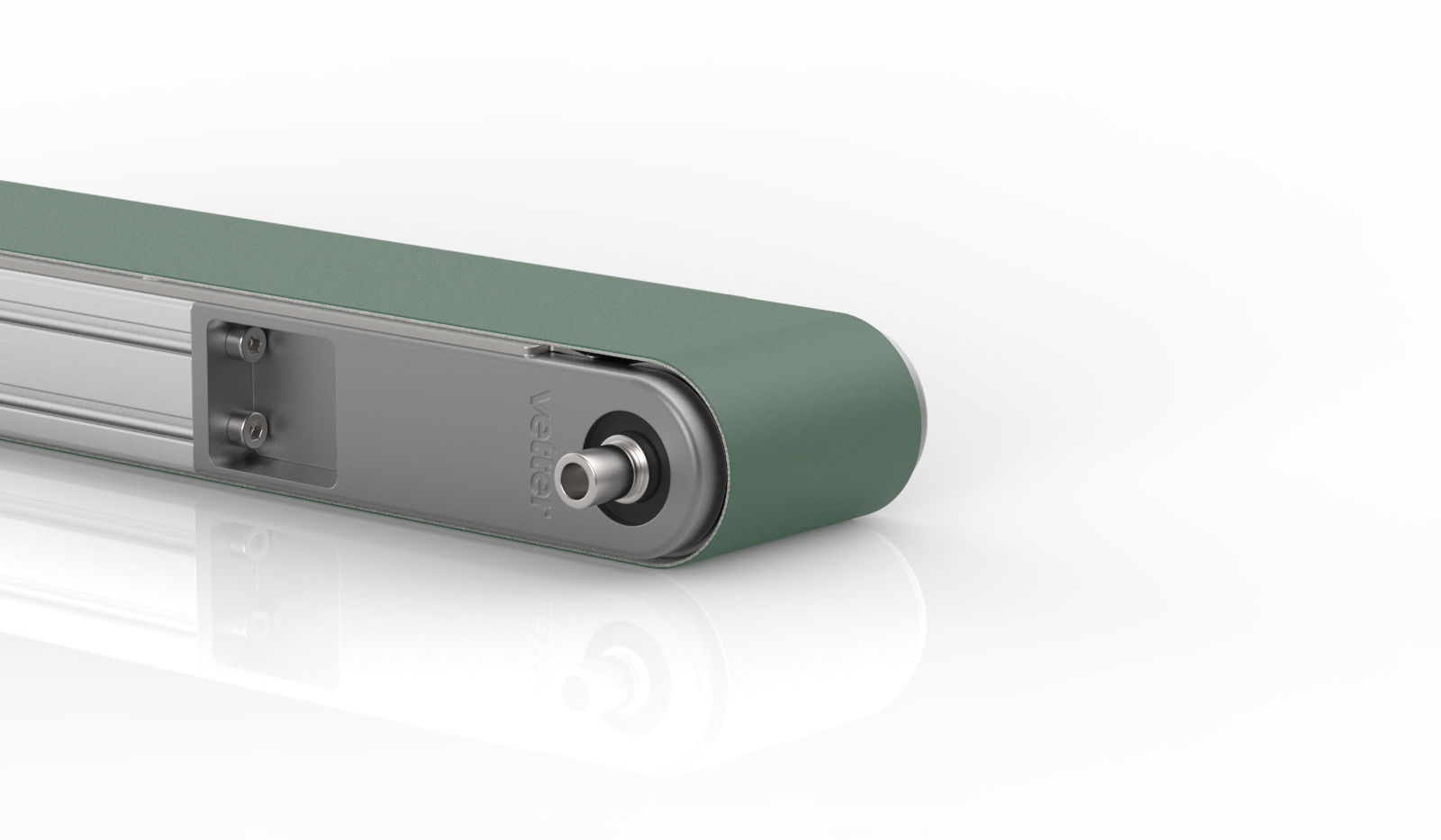

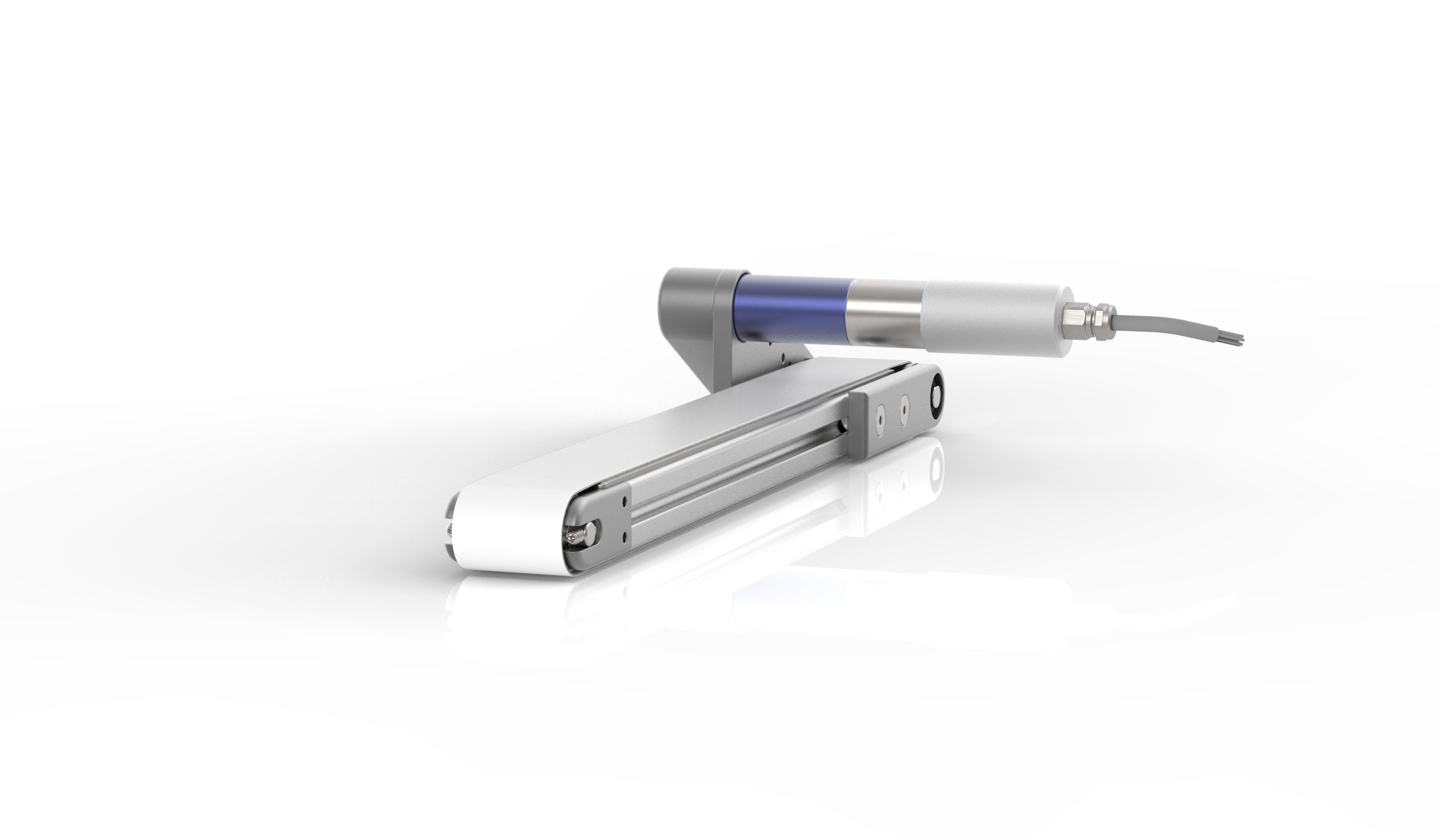

If you’d like to mount your own encoder at the conveyor, we are happy to also equip our products with an encoder shaft. You can use the connection to easily connect the external rotary encoder and access the output signals.

On request, we also produce our small conveyors without an integrated motor. Instead, we equip the conveyor with a shaft stub, which you can use to flexibly connect your own drive.

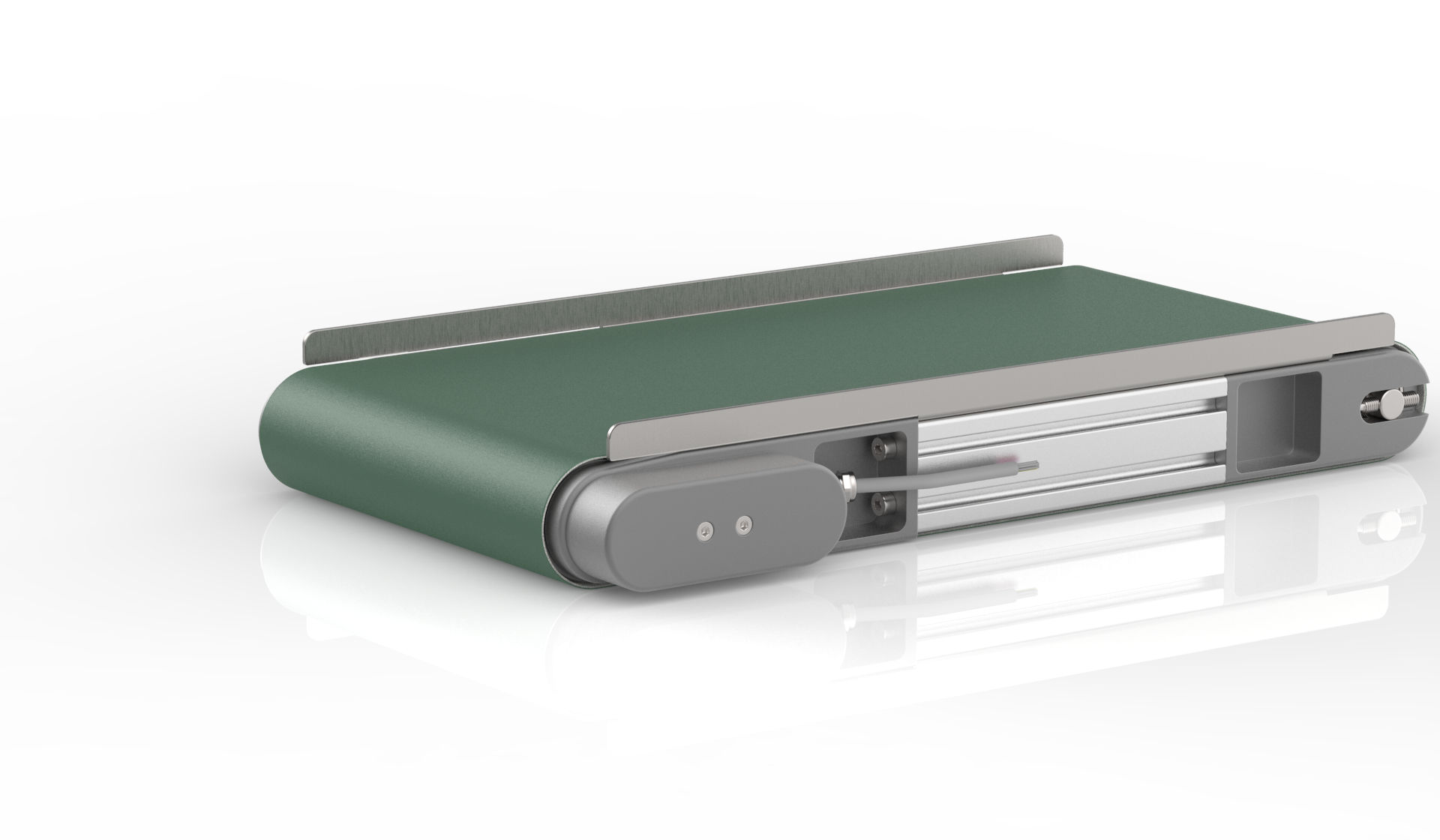

From time to time, conveyed goods require special “guidance”. To make sure parts that are round or especially light don’t fall off the belt, a special sliding plate is needed.

The small conveyor is equipped with a special sliding support instead of the usual sliding plate. The plate is manufactured from a single piece and bent upwards to form a “U-shaped groove”. This is how the integrated lateral guides are formed. We’d be happy to talk with you about the height you require.

Material: Stainless steel, which can alternatively be equipped with additional plastic lateral guides.

It is possible to add lateral guides to any of the conveyor models.

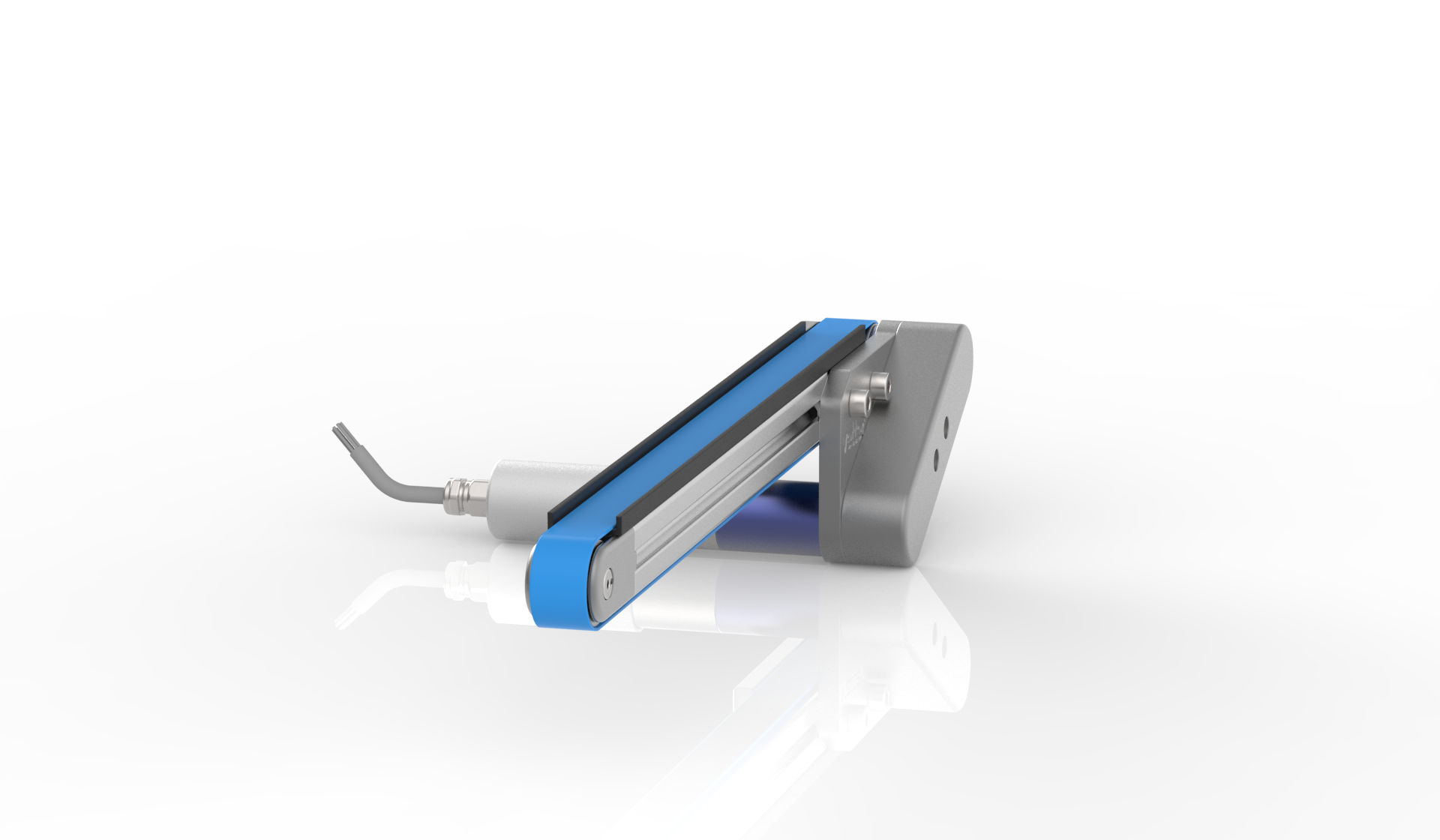

From time to time, conveyed goods require special “guidance”. To make sure parts that are round or especially light don’t fall off the belt, a special sliding plate is needed.

The small conveyor is equipped with a special sliding support instead of the usual sliding plate. This example shows a model from the modular kit with black plastic lateral guides.

It is possible to add lateral guides to any of the conveyor models.

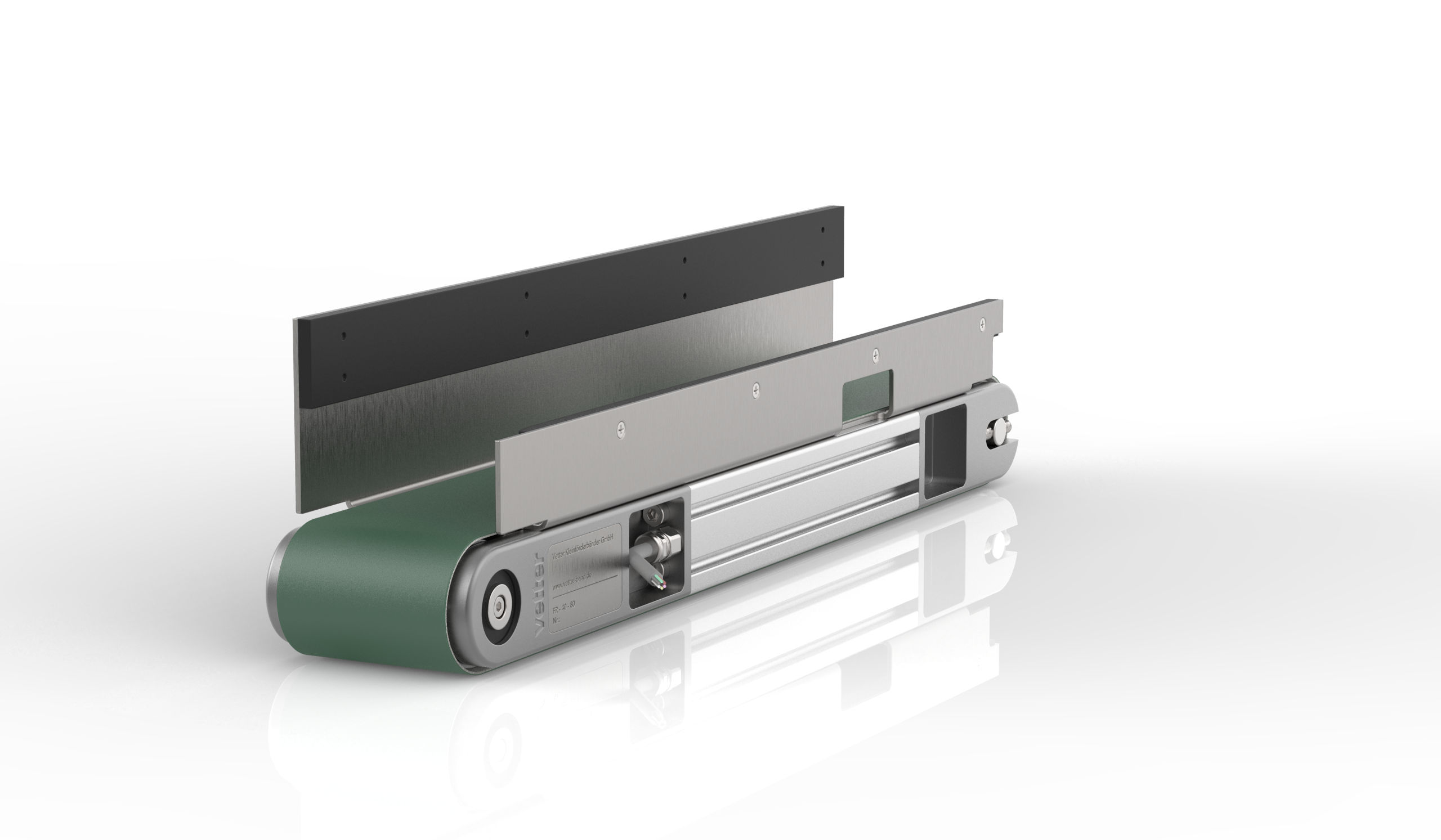

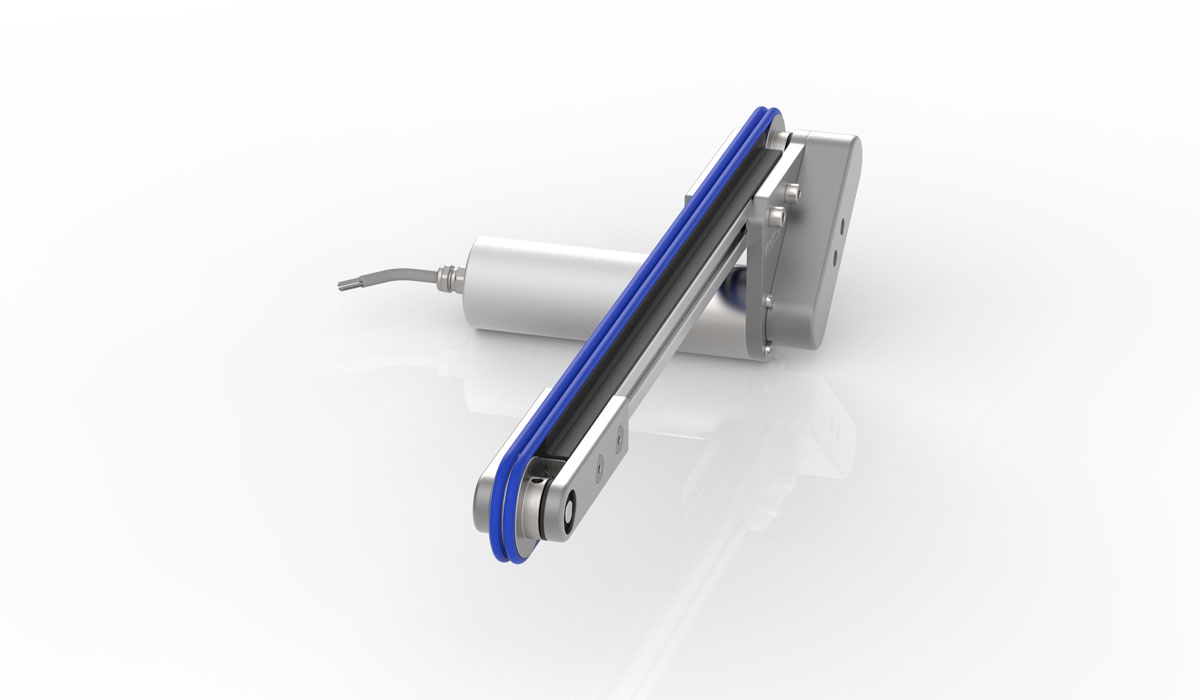

From time to time, conveyed goods require special “guidance”. To make sure parts that are round or especially light don’t fall off the belt, a special sliding plate is needed.

The small conveyor is equipped with a special sliding support instead of the usual sliding plate. The plate is manufactured from a single piece and bent upwards to form a “U-shaped groove”. This is how the integrated lateral guides are formed. We’d be happy to talk with you about the height you require.

Material: Stainless steel, which can alternatively be equipped with additional plastic lateral guides.

It is possible to add lateral guides to any of the conveyor models.

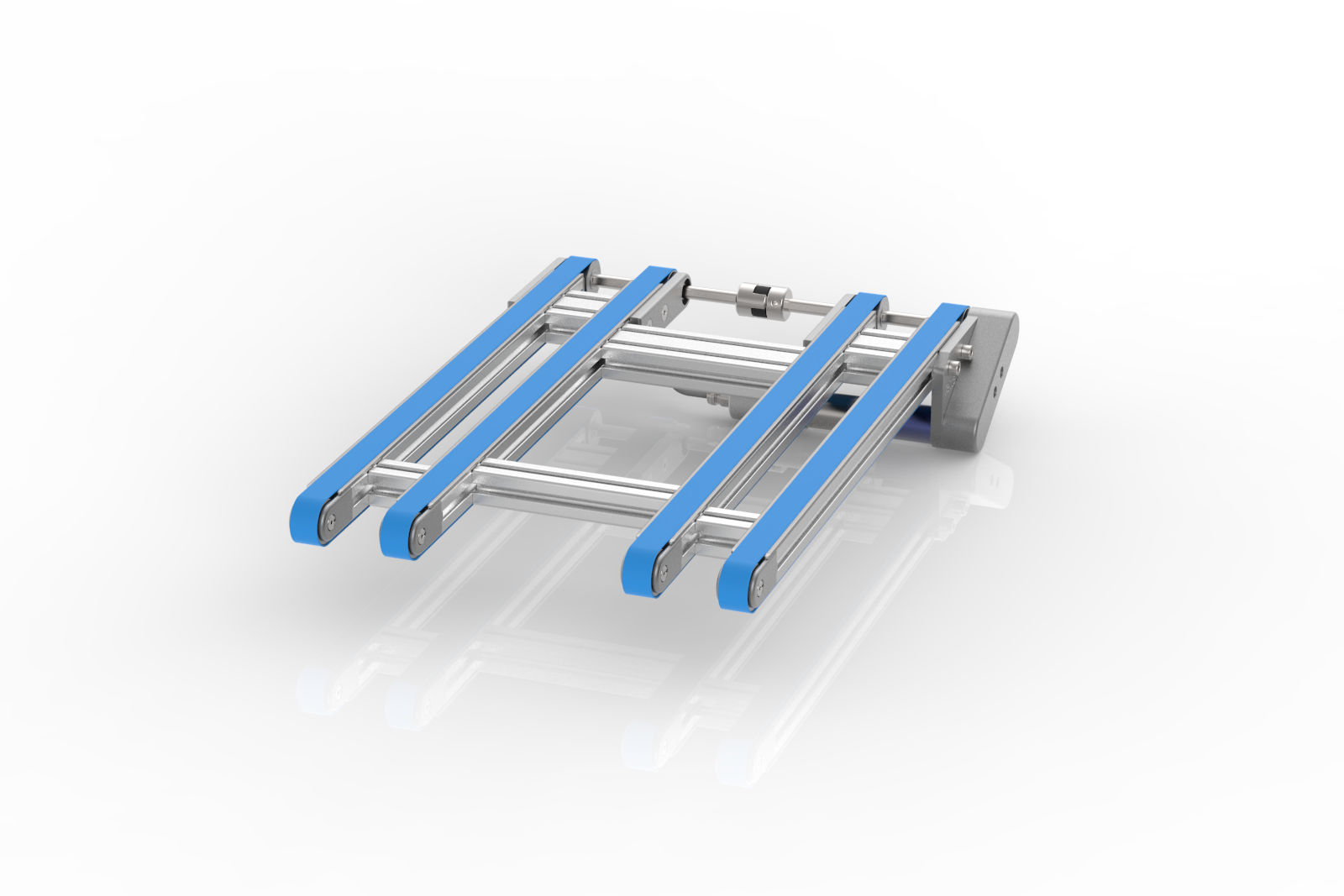

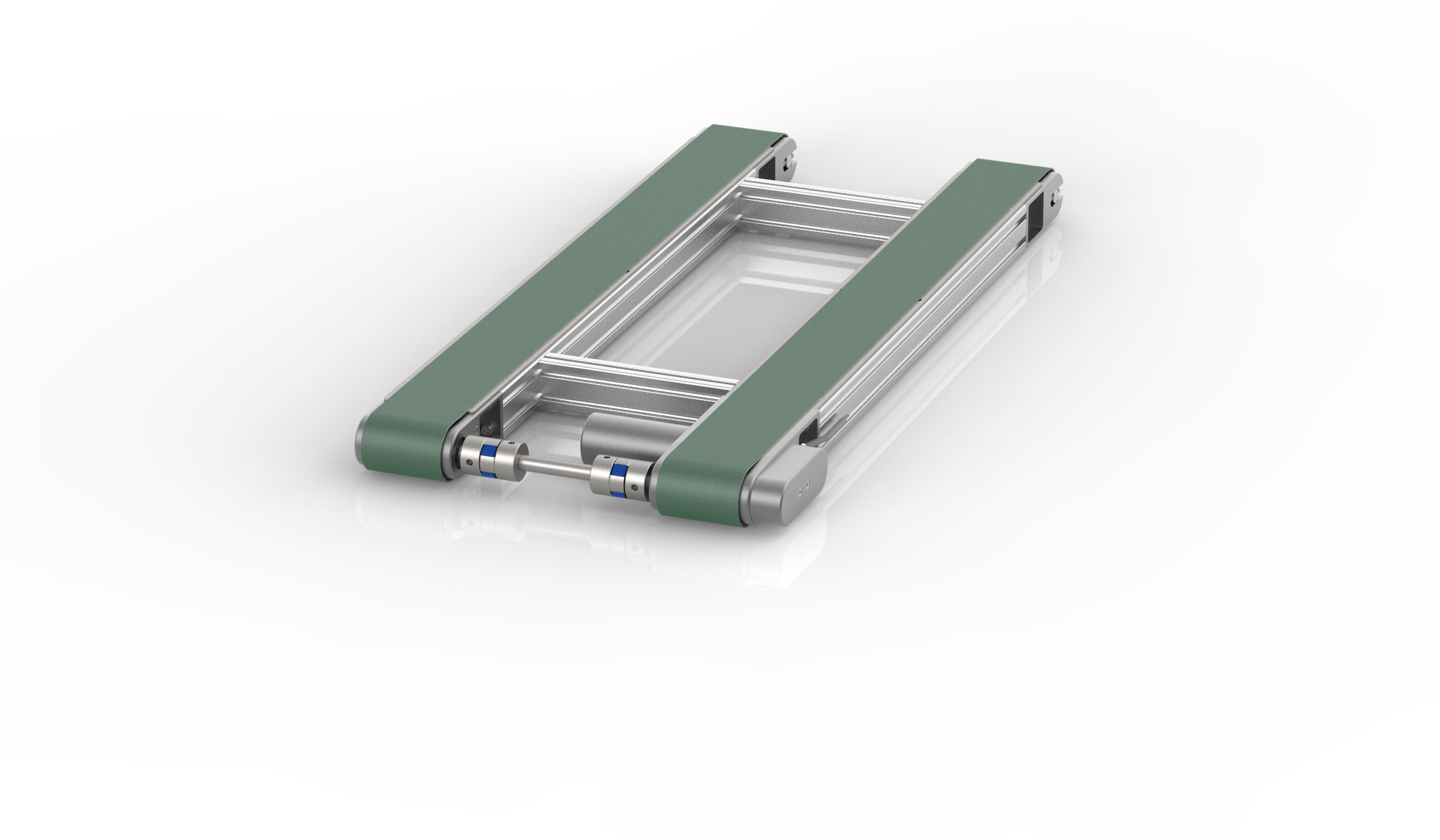

Multiple-track conveyor solutions are often required when complex products are to also hang down between the tracks.

Other conceivable application cases include testing or assembly tasks. For example, it is possible to fit stoppers or ejectors between the tracks.

We manufacture multiple-track conveyor solutions using our flexible modular kit system. The solution consists of a motor and any number of conveyor tracks. This version makes it possible for us to ensure that all conveyors run synchronously at the exact same speed. If more complex products are to be conveyed on all tracks, synchronous running is essential. On request, the transverse profiles shown in the picture can also be fitted at a different point for mounting. You are flexible with regard to housing width and in your choice of conveyor belts.

Multiple-track conveyor solutions are often required when complex products are to also hang down between the tracks.

Other conceivable application cases include testing or assembly tasks. For example, it is possible to fit stoppers or ejectors between the tracks.

We manufacture multiple-track conveyor solutions using our flexible modular kit system. The solution consists of a motor and any number of conveyor tracks. This version makes it possible for us to ensure that all conveyors run synchronously at the exact same speed. If more complex products are to be conveyed on all tracks, synchronous running is essential. On request, the transverse profiles shown in the picture can also be fitted at a different point for mounting. You are flexible with regard to housing width and in your choice of conveyor belts.

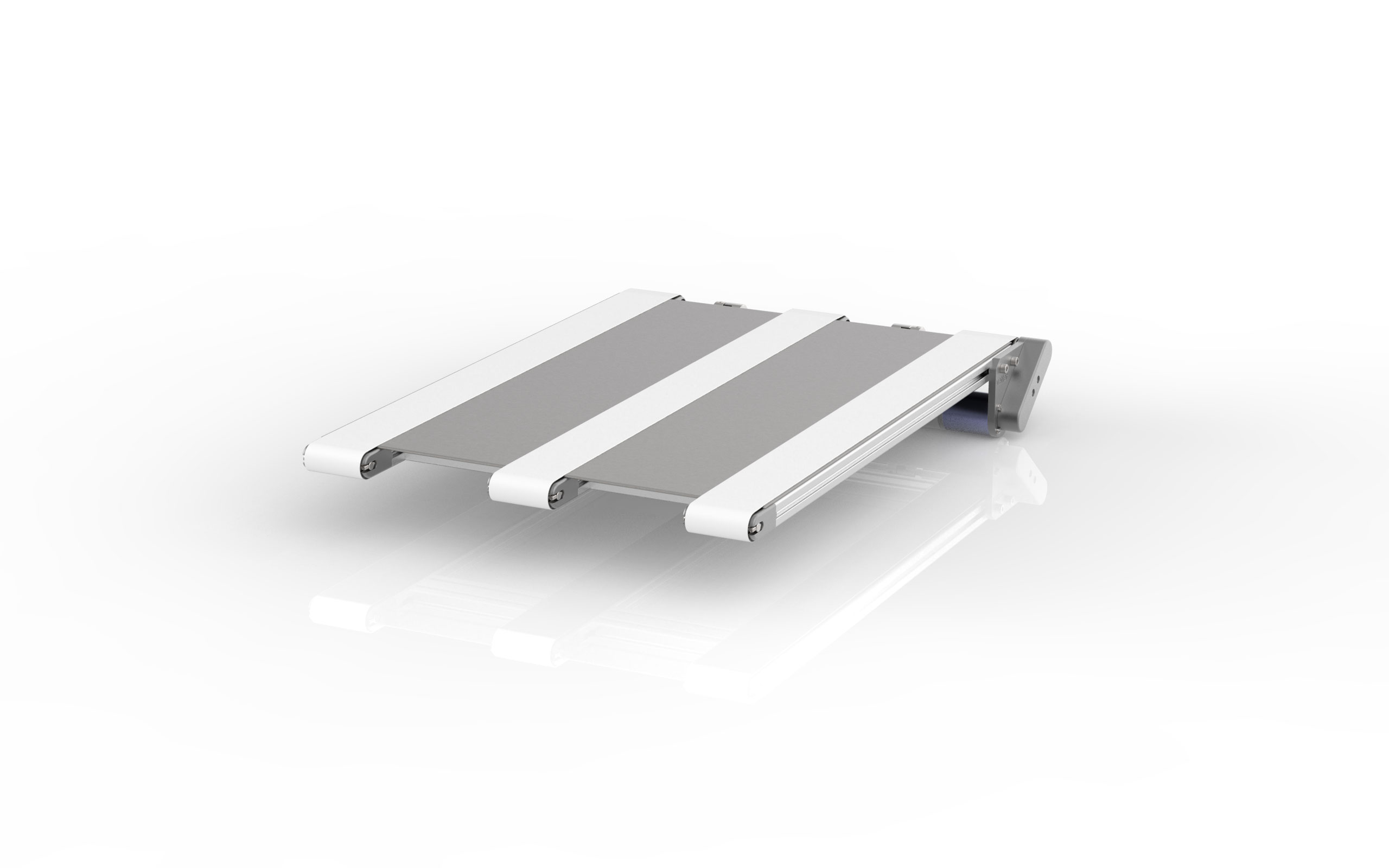

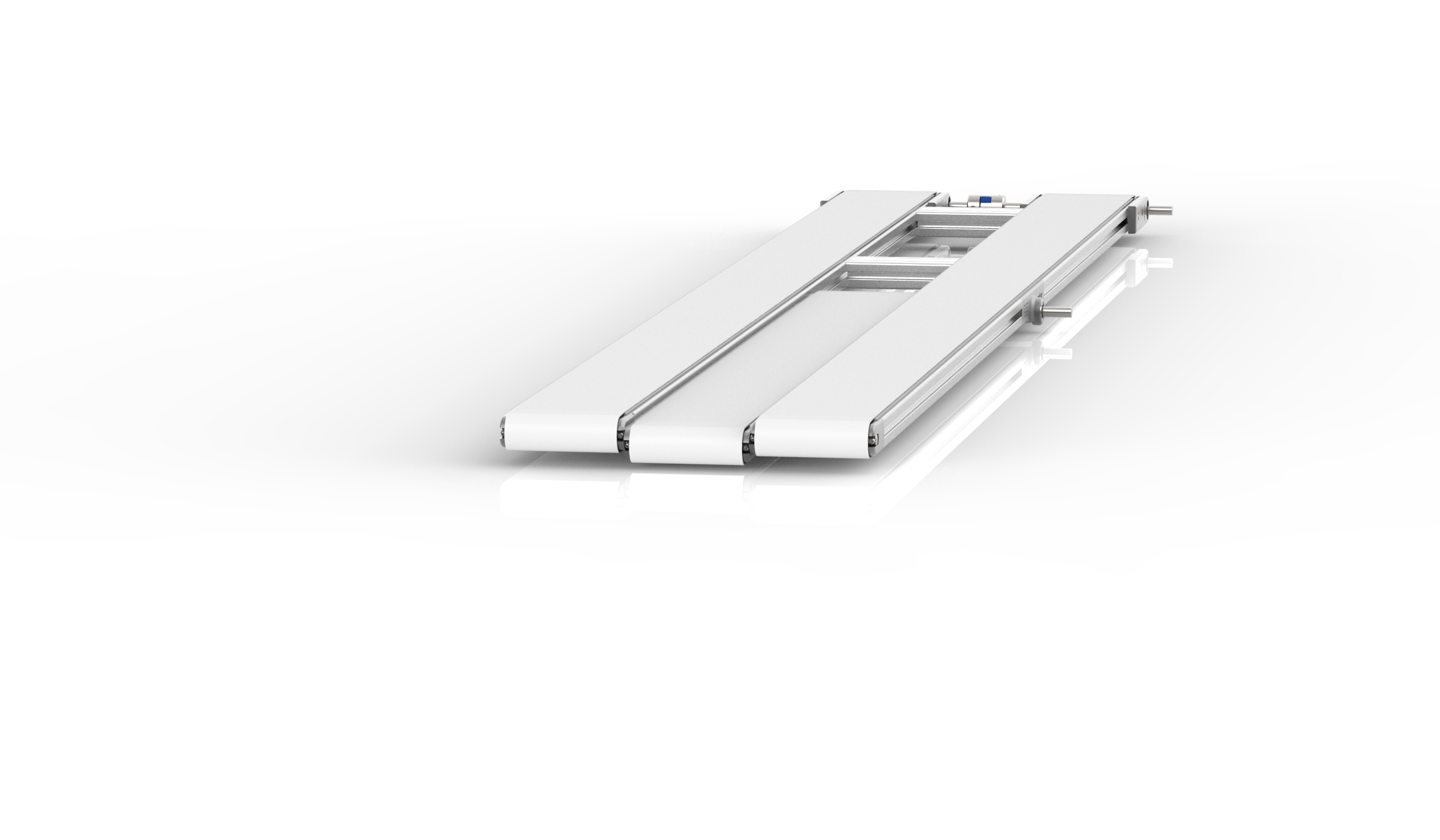

If our maximum housing width of 200 mm from the standard series is too small for your application, we can also use a multi-track solution and thus gain more width. The multi-track conveyor can be equipped with a continuous sliding plate so that there are no gaps between the conveyor tracks.

We manufacture multiple-track conveyor solutions using our flexible modular kit system. The solution consists of a motor and any number of conveyor tracks. This version makes it possible for us to ensure that all conveyors run synchronously at the exact same speed. If more complex products are to be conveyed on all tracks, synchronous running is essential. The sliding plate is made in one piece and runs across all three conveyor tracks. You are flexible with regard to housing width and in your choice of conveyor belts.

The picture shows a 3-track solution: 3 x BK-20-60 with a 400 mm wide sliding plate (corresponds to the total width).

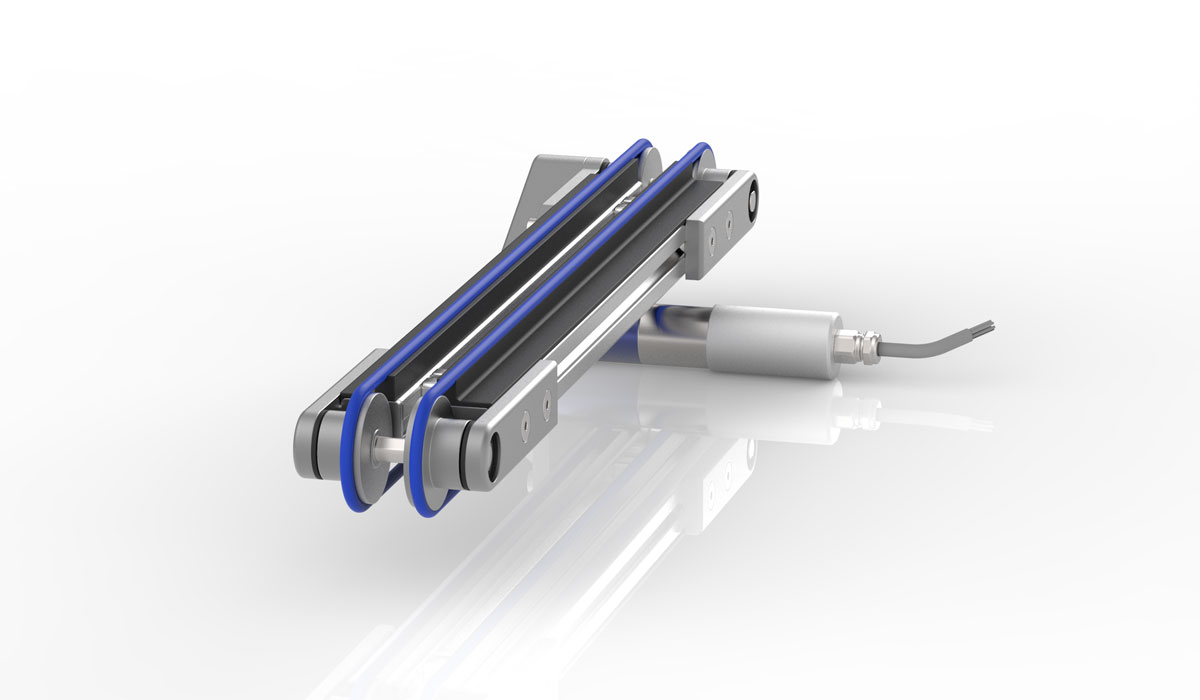

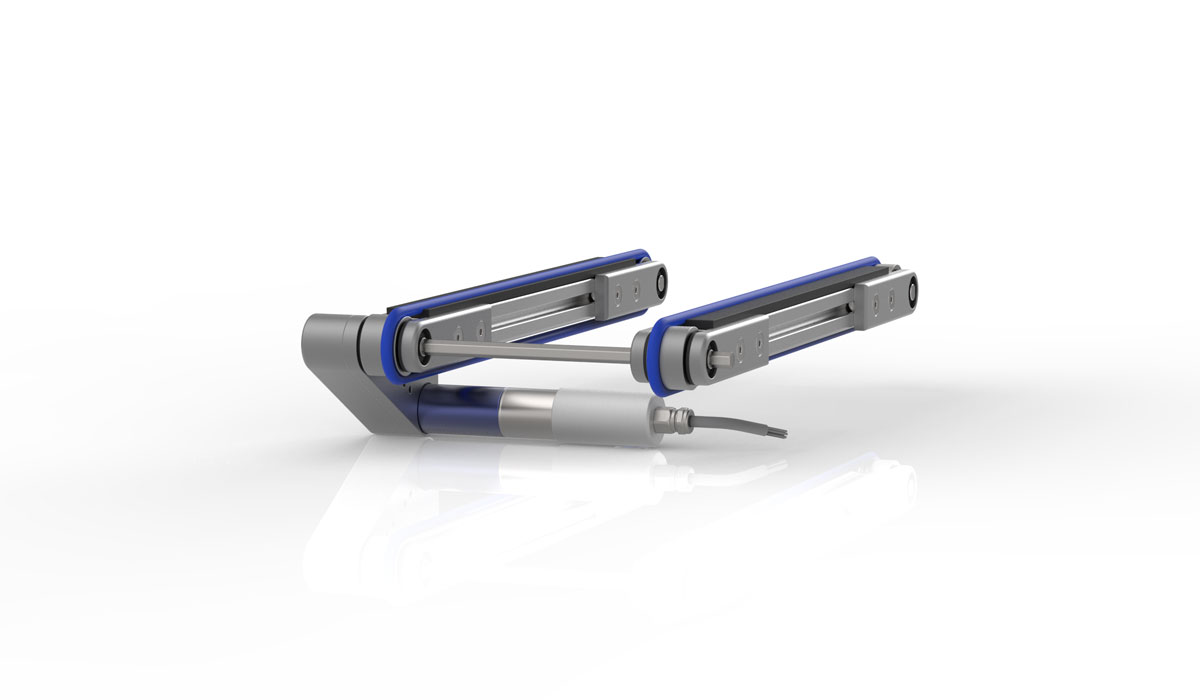

If a flat conveyor belt is not the ideal surface for your conveyed goods, it is also possible to use round belts. Round belts are always used when the product requires an exact belt line. In the example shown here, the product is also to be able to hang down between the tracks along the entire length of the conveyor.

For free conveyance of the components protruding downward, special drive and deflector rollers were used which enable the required clearance height above the drive shaft. In addition, special sliding guides were used for the round belts.

The belts are made of elastic PU material and are available in various diameters.

If a flat conveyor belt is not the ideal surface for your conveyed goods, it is also possible to use round belts. Round belts are always used when the product requires an exact belt line.

For this type of conveyor special sliding guides were used for the round belts. The belts are made of elastic PU material and are available in various diameters.

If a flat conveyor belt is not the ideal surface for your conveyed goods, it is also possible to use round belts. Round belts are always used when the product requires an exact belt line. In the example shown here, the conveyor belt should even be flexibly adjustable in track width.

For free conveyance of the components protruding downward, special drive and deflector rollers were used which enable the required clearance height above the drive shaft. In addition, special sliding guides were used for the round belts.

The belts are made of elastic PU material and are available in various diameters.

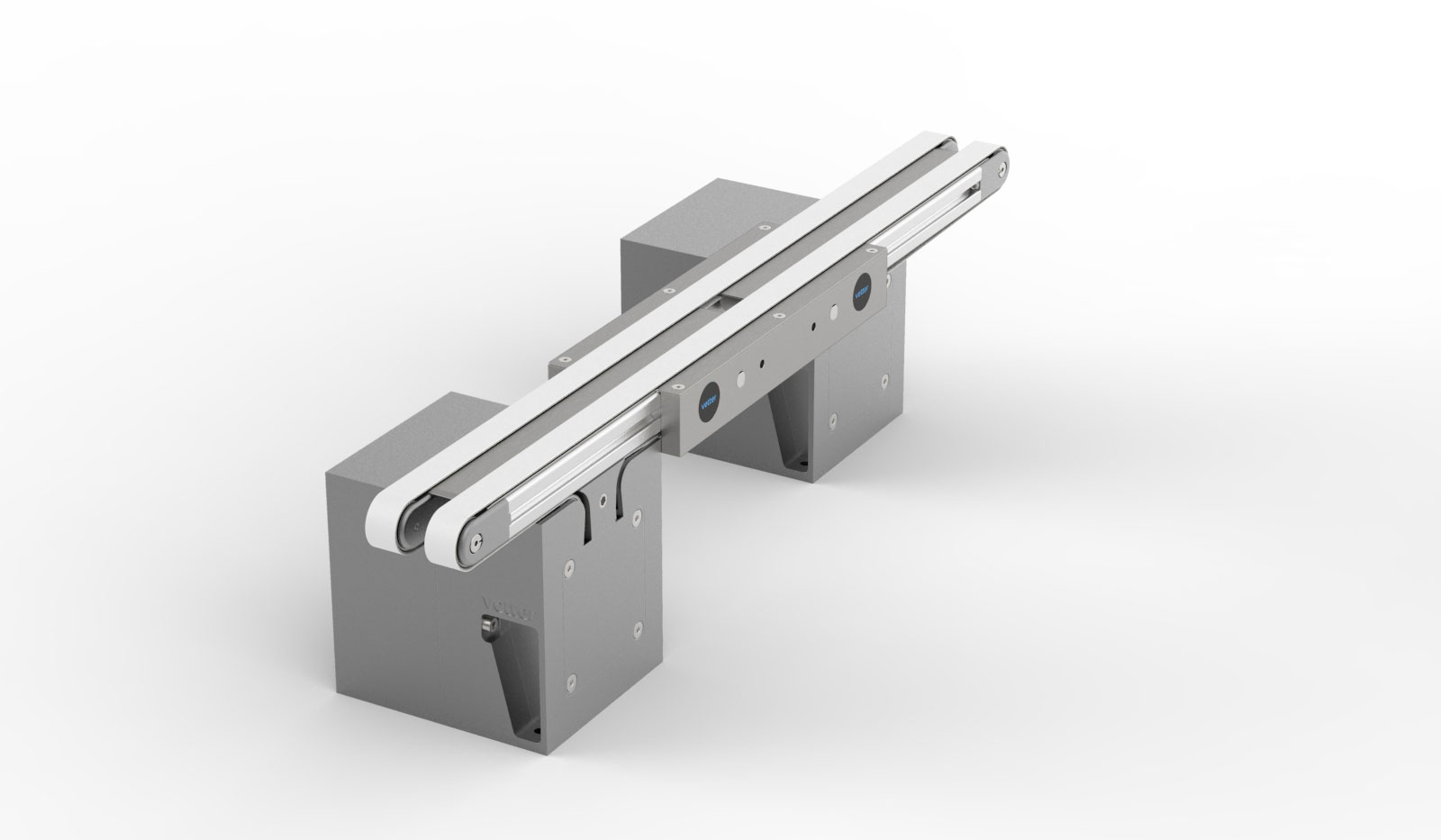

Multiple-track conveyor solutions are often required when complex products are to also hang down between the tracks. Other conceivable application cases include testing or assembly tasks. For example, it is possible to fit stoppers or ejectors between the tracks.

We can also use coupled conveyors if our maximum housing width of 200 mm from the standard series is too narrow for your application and thus gain more width.

In addition to our multi-track conveyors from the modular kit system, we also have the option of coupling small conveyors from the series with transverse drive. The solution consists of a motor and any number of conveyor tracks. This version makes it possible for us to ensure that all conveyors run synchronously at the exact same speed. If more complex products are to be conveyed on all tracks, synchronous running is essential. On request, the transverse profiles shown in the picture can also be fitted at a different point for mounting. You are flexible with regard to housing width and in your choice of conveyor belts.

Compared to the modular system, the advantage here is that the conveyor solution above and below the transport track is completely free of interference contours due to the transverse motor. You can also use even wider conveyors from our standard range up to a housing width of 200 mm each.

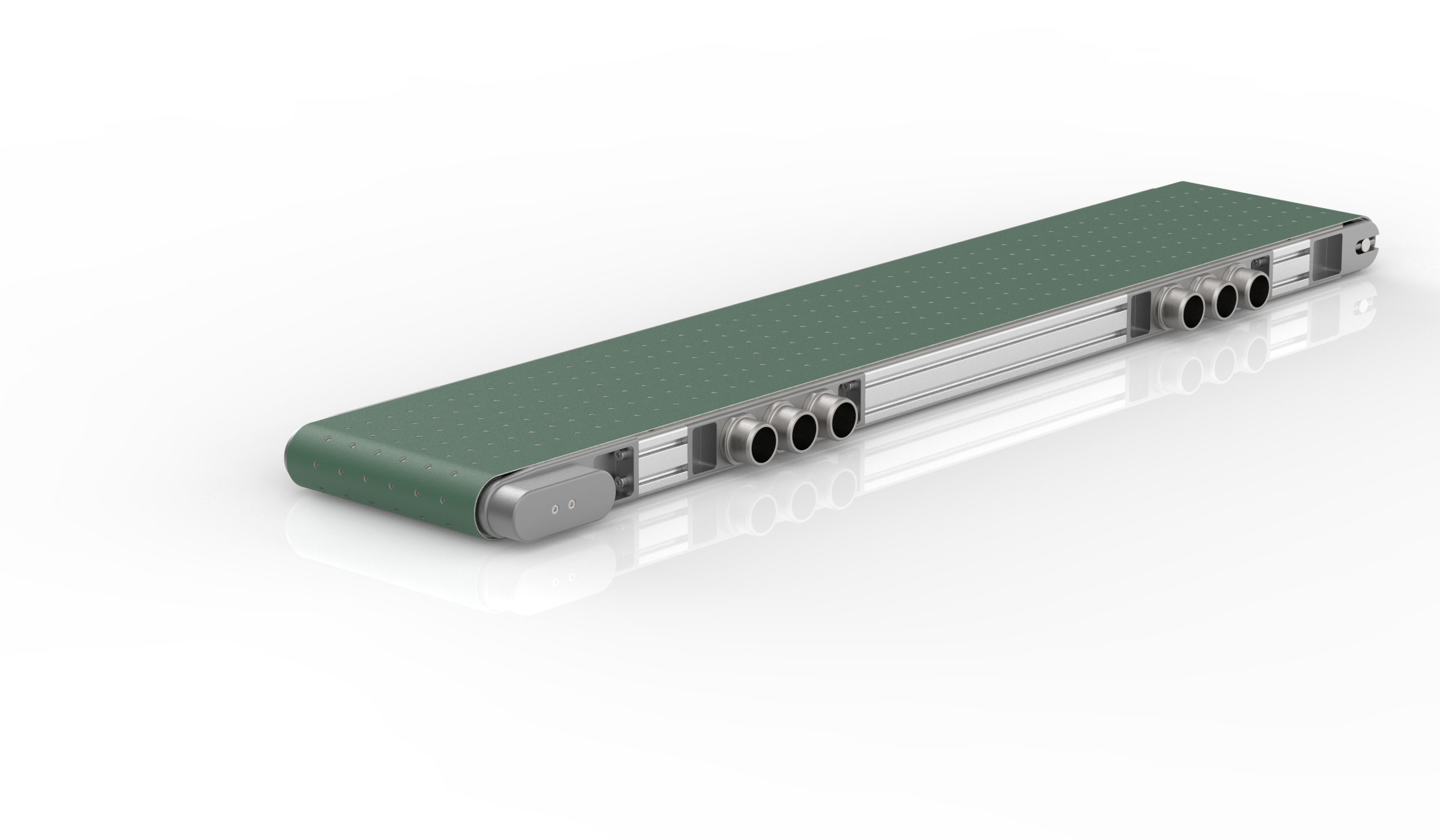

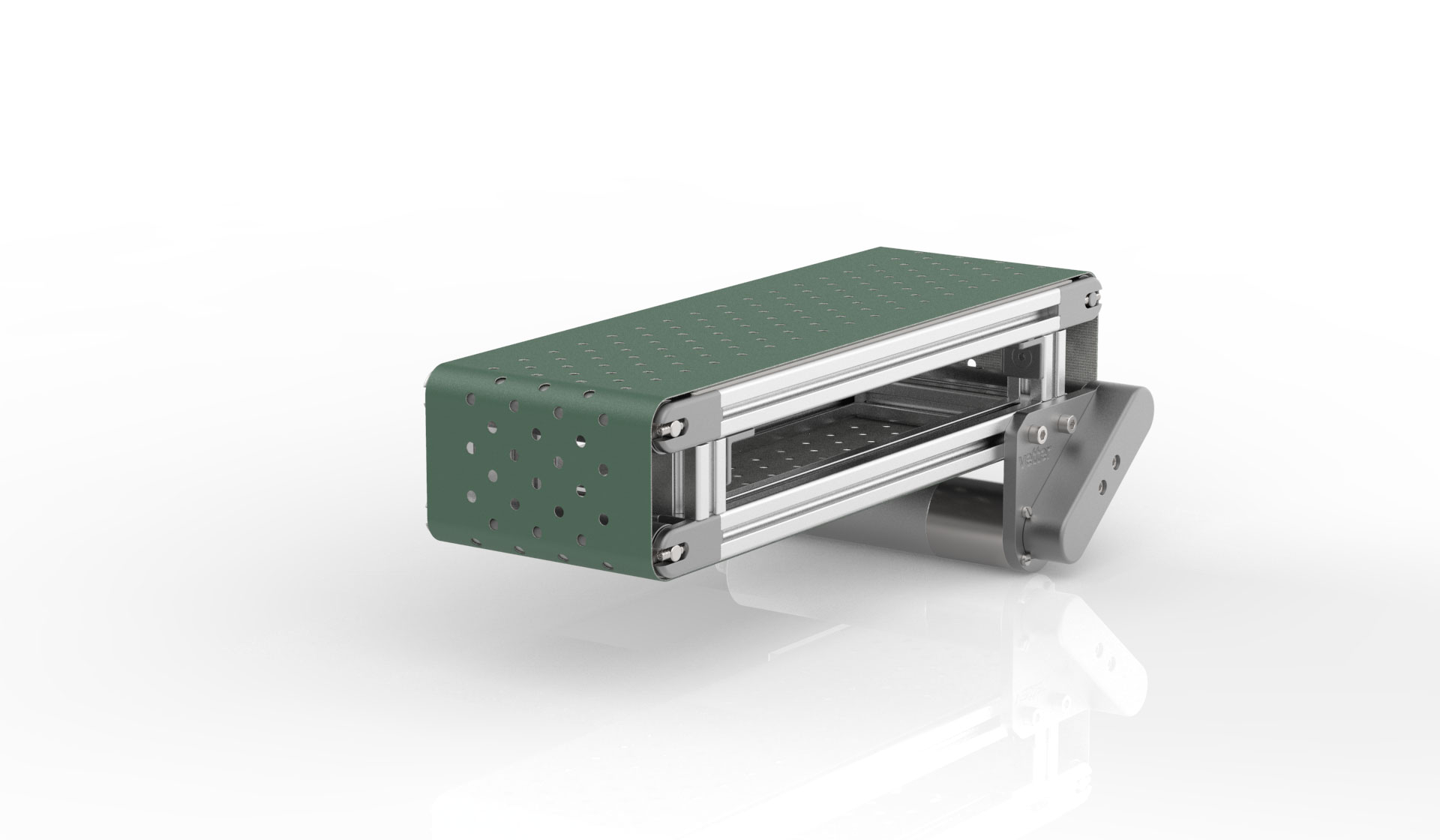

The small conveyor with vacuum function is often used to transport products which are particularly lightweight and which under no circumstances are to be permitted to “fly off”. In this case, our customer manufactures small plastic bags and needs a small conveyor for intermediate transport of the product which provides the option of keeping the bags on the belt by means of suction.

The solution was a conveyor belt with many perforations through which intake air can flow to create the vacuum. The foils to be conveyed thus remain lying in the desired position on the conveyor belt.

The housing of the conveyor is equipped with several connections for the intake air in order to enable high air throughput.

Our customer was looking for a solution to transport paper that is to be printed on the conveyor. For this it was necessary to provide additional adhesion on the conveyor belt.

A vacuum function is useful for transporting particularly light goods. Our conventional vacuum conveyor will be provided with several connections through which the customer can connect the intake air.

In this case, our customer had a different solution: The vacuum should be generated by simple case fans, which are placed in the conveyor below the transport belt. In order to create space for the case fans, our customer duplicated the Vetter modular kit conveyor and thus created the required free space. The entire conveyor belt was driven with one motor and one drive wheel. In order to increase the friction, we had the drive wheel additionally coated.

Again and again we are amazed about the applications our customers design with our conveyor series! Our modular kit was particularly suitable as a basis for this application. This project once again shows the flexibility of our Vetter small conveyors and the wide range of possible application areas.

Modular conveyor consisting of 3 transport tracks, of which the middle track was mounted at a different height. The item profiles as connecting pieces can also be mounted flexibly elsewhere.

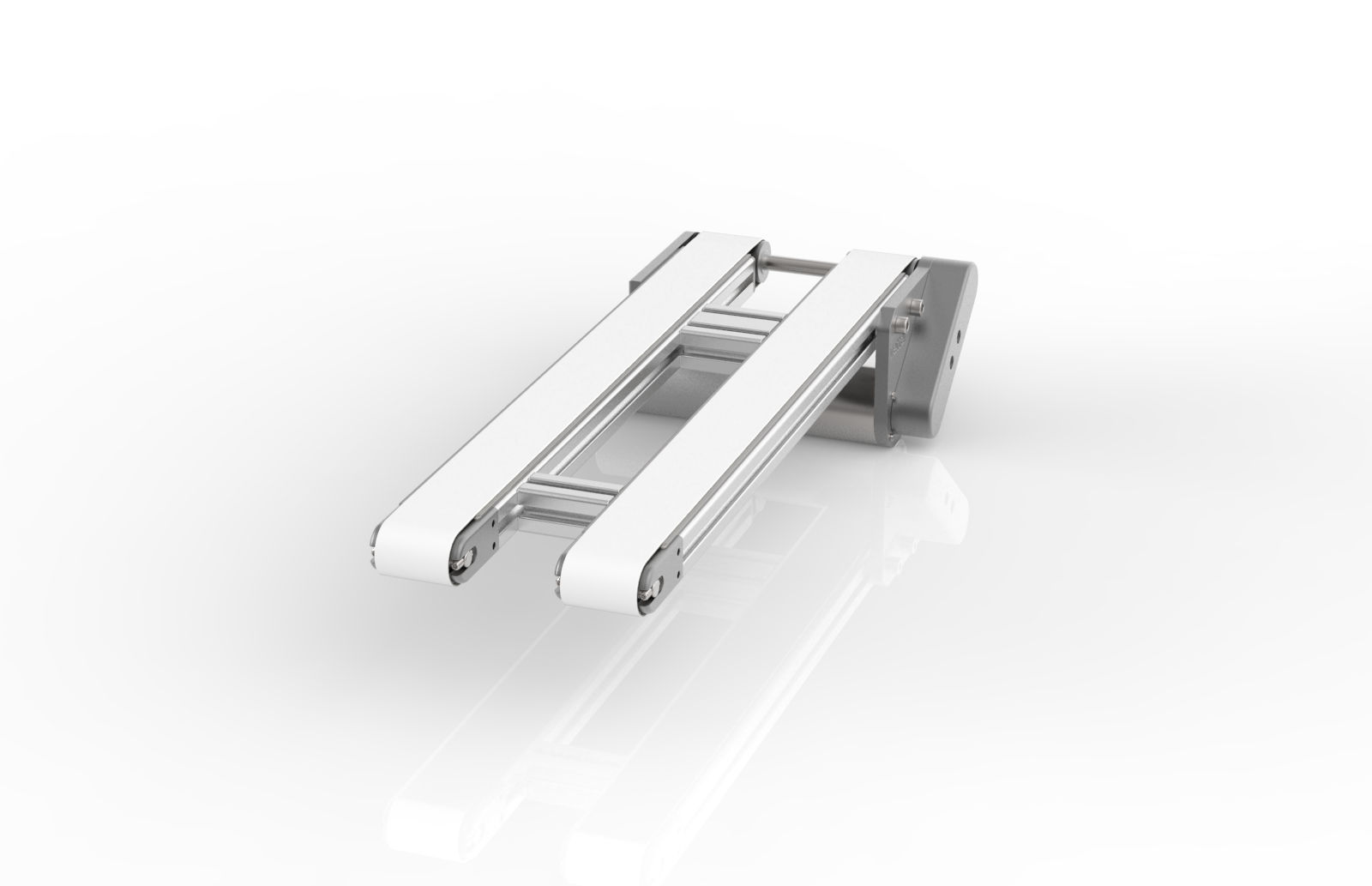

Our customer requires a conveyor belt system for printing parts while they are being conveyed. A separate print head is to be integrated into the solution, which is brought as close as possible to the transported goods from below.

Two conveyor belts from the centre drive series are arranged in parallel with a gap for easy access. The print head is positioned in the corresponding space. As a result of the special design of the belt deflection, it is possible to move the print head upward until it is 5 mm away from the goods being conveyed.

The drives belonging to the centre drive series can be moved across the entire length of the profile and can therefore be positioned individually.

We are flexible with our modular series: If the standard position of the motor below our conveyor does not fit into your application environment, we simply place the motor above the transport track.

If especially small parts are to be transferred from one conveyor to the next one, a special solution is needed. Another knife edge use case is when products are to be scanned from below while being conveyed from A to B.

Although the roller diameter of Vetter small conveyors is already small, further reduction is necessary. With roller diameters of 5 and 8 mm, especially small parts can be transferred from one conveyor to the next one without any problems.

The gap between the two belts is thus considerably reduced and can, for instance, also be used for scanning the products from below.

For this application, we have special belts in our range which we have successfully tested for the increased load at the knife edge. On request, we can also rely on belts for this application, which are endless and therefore have no weld seam. This provides an even calmer and more accurate runnability.

For use in sterile environments, e.g. in the pharmaceuticals industry or in food processing, the requirements our products must meet are particularly strict. The objective is to create a product which offers no chance for dirt particles or impurities to accumulate. Recesses and grooves of all kinds must be avoided.

For this special case, we have further optimized our “Q series” (small conveyors with transverse drive). In the case of the Q series, the drive is integrated in the housing for the most part and comes with an external cover for protection against contact. The drive housing can thus be optimally sealed to protect against the ingress of dust and liquids.

The example here shows a further optimization which results from replacing conventional profiles with sealed profiles.

The solution is possible for all conveyors in which profiles are integrated.

See a selection of our custom solutions in motion! The video shows exhibits from our trade fair appearance at Motek 2019 in Stuttgart.

With this small conveyor, we have further miniaturized our modular kit series to a belt width of just 10 mm. A small and flexible conveyor solution with timing belt and easydrive system was created (BK-20-10).

Test setup on customer request: The task is the precise hand over between two conveyors through electronically controlled synchronous operation. Each conveyor should have two tracks due to the desired transport width.

You need a conveyor with a very special "grip" for your products? With our small conveyor with vacuum function, we can easily suck in your products on the belt!

Cookie settings

This website uses cookies that enable you to use services offered by external providers, such as YouTube or Google Maps. The legal basis here is Art. 6 DSGVO (1) a.

Here you can object to the anonymized recording of your user behavior by MATOMO. For this purpose, we store a cookie on your computer to respect this decision also on subsequent visits.

Please note that depending on your settings, some functions may not be available.

You can find more information in our Privacy policy